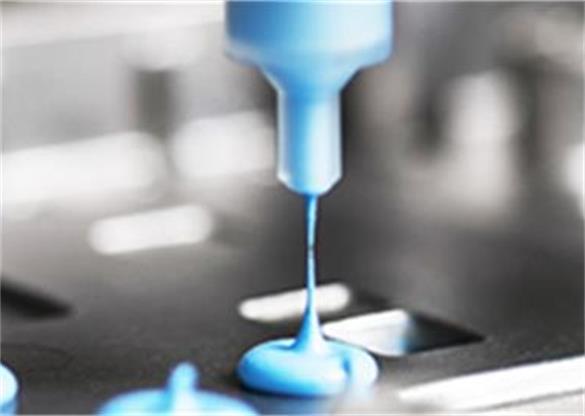

Low Pressure Molding with PA hot-melt materials is a process typically used to encapsulate and environmentally protect electronic components. The purpose is to protect electronics against moisture, dust dirt and vibration.

The process was initially invented by Henkel in Europe in the 1970s where experiments with hot-melts were used to seal connectors and create strain reliefs for wires. The first commercial use of the Low Pressure Molding process was in the automotive industry. The driving force was to replace toxic and cumbersome potting processes, shorten cycle time, lighter parts and environmentally protect components.

Injection Pressure

Injection Temperature

LPMS selects high performance PA hot-melt adhesive, which has excellent mobility. The adhesive takes very small pressure to make it flow to mold, therefore, the products successfully over-molded without causing any harm in the process, greatly reducing the defect product.

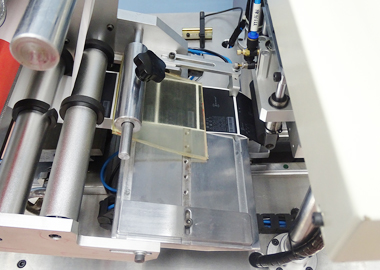

LPMS have standard production service department and manufacturing shop to provide small/larger quantities productions service and testing service. Service includes SMT, DIP plug-in, lead-free process, welding process, low pressure molding, testing, package and new part design service.

Copyright ? 2015-2018 LPMS International Ltd. All Rights Reserved.